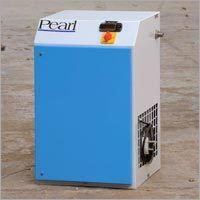

Heatless Compressed Air Dryer

Price 50000.00 INR/ Unit

Heatless Compressed Air Dryer Specification

- Heating Power

- Electric

- Usage

- industrial

- Power Source

- Electric

- Size

- 2240x900x1800

- Product Type

- Air Dryer

- Length

- 1023.62 Millimeter (mm)

Heatless Compressed Air Dryer Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 6 Week

- Sample Available

- No

- Main Export Market(s)

- Middle East, Western Europe, Eastern Europe, Africa, Central America, South America, Asia, North America, Australia

- Main Domestic Market

- All India

About Heatless Compressed Air Dryer

Heatless Compressed Air Dryer

Since our establishment in the industry, we are engaged in manufacturing and supplying the Heatless Compressed Air Dryer. All these dryers are widely used for producing uncontaminated air by removing solid, vapor and liquid contents. Our dryers are perfectly synchronized with the quality assured components sourced from the authentic market vendors. Further, we make available the Heatless Compressed Air Dryer after conducting quality testing approaches.

Features:

- Operates on low dew point

- Instant dry air availability

- Convenient to install and operate

Further Details:

HOW IT WORKS

The contaminated compressed air is made to pass thru Prefilter PF (for removal of solids & liquids) and Oil Removal Filter ORF (for removal of oil vapour) before entering Tower A1 thru a 3-way valve where it is dried by the adsorbent. Dry air exits the Dryer thru the After filter AF (where fine particles, if any are trapped) for use. A part (10 - 15%) of the dry air is expanded in the Purge Control Valve (PCV), passed thru Tower A2 to regenerate the adsorbent and exhausted out of its Purge Exhaust Valve (PEV) thru a Silencer (S).

Prior to reversal of functions of Towers A1 & A2, PEV of Tower A2 is closed and its pressure slowly rises and equalizes with pressure of Tower A 1. The reversal is then effected and Tower A2 comes under adsorption & Tower A1 is under regeneration. This cyclic operation is then repeated continuously & automatically thru a sequential control timer.

Features

- Pressure equalization - ensures dry air supply is continuous and at constant pressure.

- Electronic Timer - Highly precise and fail-safe with excellent repeatability

- Low Dew Point - Constant atmospheric dew point of - 40 C or below.

- Instant dry air availability.

- Easy to install & operate, requiring very few, low-cost spares.

- Low Power Consumption - Approximately 50 Watts only.

- Equipped with Silencers - low noise level.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Compressed Air Dryers Category

Refrigerated Compressed Air Dryer

Price 50000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Power Source : Electric

Product Type : Air Dryer

Dimension (L*W*H) : 360x475x570 Millimeter (mm)

Size : 2240x900x1800 MM

Refrigerated Type Compressed Air Dryer

Price 50020.00 INR / Unit

Minimum Order Quantity : 1 Piece

Power Source : Electric

Product Type : Compressed Air Dryer

Dimension (L*W*H) : 420 x 400 x 430 Millimeter (mm)

Size : 2240x900x1800 MM

Heatless Air Dryer

Price 50050.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Product Type : Air Dryer

Dimension (L*W*H) : 1810 x 1200 x 1300 Millimeter (mm)

Size : 2240x900x1800 MM

Refrigerated Compressed Air Dryers

Price 50050.00 INR / Unit

Minimum Order Quantity : 1 Piece

Power Source : Electric

Product Type : Compressed Air Dryers

Size : 2240x900x1800 MM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS