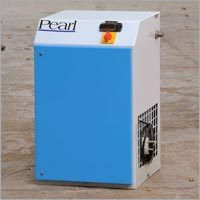

Refrigerated Dryers

Product Details:

- Product Type Refrigerated Dryers

- Dimension (L*W*H) 900 x 600 x 1000 Millimeter (mm)

- Usage industrial

- Heating Power Electric

- Power Source Electric

- Click to View more

Refrigerated Dryers Price And Quantity

- 1 Piece

- 50000.00 INR/Unit

Refrigerated Dryers Product Specifications

- Electric

- industrial

- Refrigerated Dryers

- 900 x 600 x 1000 Millimeter (mm)

- Electric

Refrigerated Dryers Trade Information

- Cash in Advance (CID) Cash Advance (CA)

- 10 Piece Per Month

- 6 Week

- No

- Middle East Africa Western Europe Australia Eastern Europe Central America South America Asia North America

- All India

Product Description

Refrigerated Dryers

Considered as the most economical and reliable compressed air treatment equipments, our gamut of Cycling Refrigerated Dryers is supplied by us. The most important task of these dryers is to remove moisture in compressed air system installations. We manufacture these dryers at par with the international standards of quality and functionality. According to the application requirements, these Cycling Refrigerated Dryers can be engineered with different configurations and capacities.

Features:

- Unmatched operations

- Easy usage

- Maintenance free

Further Details:

Wet Compressed air undermines efficiency of smallest to the largest pneumatic system. Therefore, moisture removal in compressed air system installation is a must. The drying of Compressed air by Refrigerated Air Dryer is the most economical and reliable process of compressed air treatment. The incoming saturated, moist air is precooled in the Air - to - Air Heat Exchanger by the outgoing dry chilled air. In the process, a greater part of Water Vapour gets condensed into liquid moisture. Further moisture separation takes place in the Freon -to- Air Heat Exchanger where air is chilled to a temperature of +2 Deg. C. and moisture condenses. This temperature is termed as pressure 'Dew Point'. The Moisture Separator removes the condensate by an Automatic Condensate Trap.

Features

- User Friendly

- Easy To Install

- Automatic Operation

- Low Power

- Indigenous Design

- Prompt After Sales Service

- Low Noise Level

- Interlocking Facility With Air Compressor

- Maintenance Free

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+